Our mission doesn't end once our system is delivered. To help our clients achieve their goals, we support them throughout the life of their projects. Our client support team is on hand 24/7 to ensure our systems are commissioned and functional, and to enable our clients to get the best possible performance from our solutions

Robotic Solutions & Services

Energy asset operators are seeking for ways to secure the uptime of their assets, while drastically reducing costs, HSE risks and GHG emissions. Embedding robotics in their operations is a way to achieve these objectives.

Leveraging 35 years of experience in developing and deploying robotics solutions in harsh environment, we have matured an offering to execute remotely Inspection, Maintenance and Repair (IMR) operations in harsh environments (Marine environment, hot, cold, contaminated, irradiated or explosive conditions, remote locations) relying on:

- A proprietary supervision to remotely operate a heterogeneous fleet of robots.

- Access to a wide range of robots fit for client applications, be it for aerial, ground of subsea applications, and for any harsh conditions (ATEX, corrosive, contaminated).

- Unique capabilities to assess feasibility and ROI from technology through in-house methodology for O&M plans analysis, a proprietary simulation tool and indoor and outdoor testing facilities.

Over the years, we have developed a unique know-how in dexterous force feedback robotics.

Our passion for solving the issues of our clients combined with our technical capabilities and agnostic approach on hardware allows us offer our clients high end robotics based O&M services.

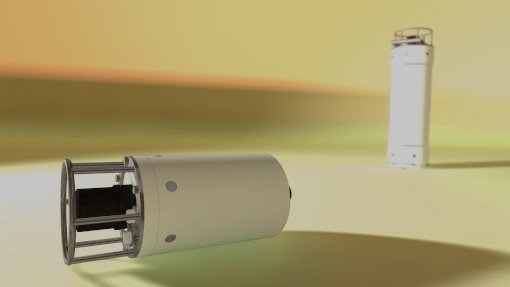

Monitoring Solutions

At Cybernetix, we have developped a rich know-how and a wide portfolio of Asset Integrity Monitoring solutions for the oil & gas and offshore renewables industries with applications such as pipelines, risers, cables, mooring systems, TLP tendons, structural health monitoring relying on:

- A proprietary Data Acquisition and Management Software Cyxense® Surveillor.

- End to end in-house system design, integration and qualification to applicable standards and regulations.

- Highly reliable and low consumption solutions based on non-intrusive retrofittable sensors.

Our teams support our customers 24/7.